I’ve been slowly and steadily making progress on printing with my new Kelsey press. It’s not a large machine, and doesn’t have nearly the total force of an etching press or even a larger floor standing letter block press. But if it’s precisely aligned and well inked, it turns out it does pretty well.

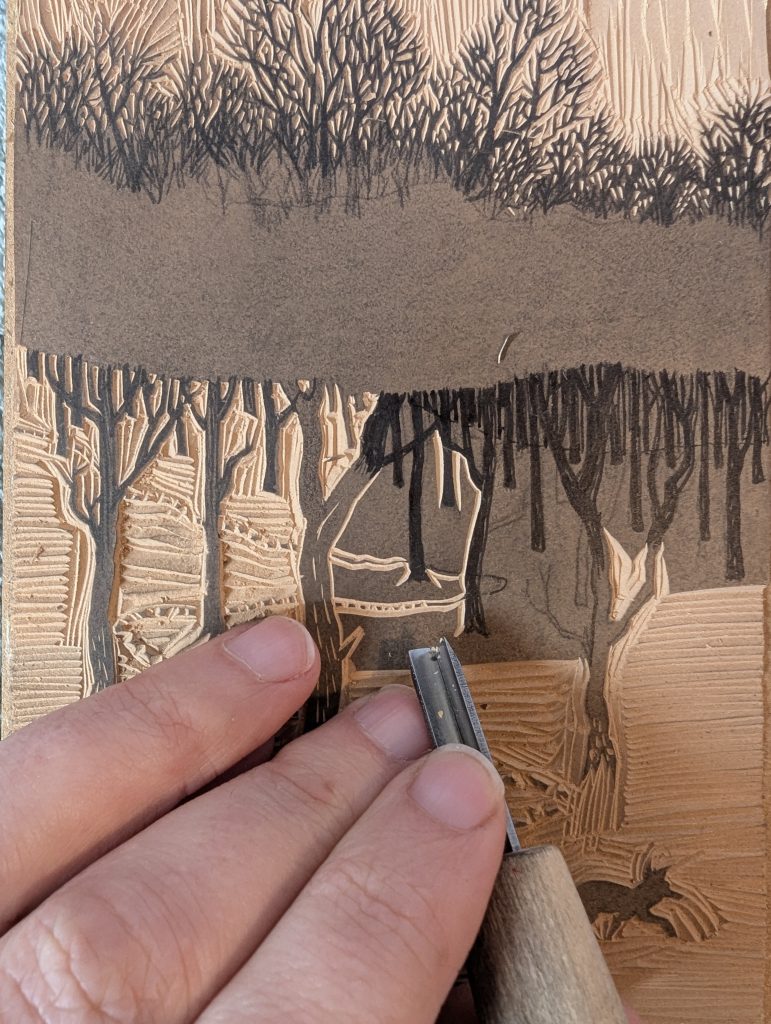

There were a few structural problems I had to identify and solve. First, it turns out one of the rails that the roller trucks ride on for inking was almost a tenth of an inch lower than the other rail. There can be wear on these rails over time, though that much difference was surprising and might just represent original casting tolerance. When used for letter printing there is so little surface area that precision can be much more forgiving. To get a good inking and impression on a block print requires everything to be very well aligned on such a little press. I learned this all while working on my second carving:

But it was still quite challenging to get even inking. So I spent more time reading and fiddling. The press is designed for type that is precision ground to “type height” at 0.918″ tall. I’ve been mounting my lino to MDF boards which is close to but not exactly tall enough. So in addition to adjusting the rail height, I needed to shim up the back of the carriage as close to exact type height as possible. I used Tympan which is wax impregnated paper that allows precision shimming without compressibility during the impression.

I learned all this while working on my third print on this press, which is now the closest I’ve gotten to a perfectly clean impression. You can see the original sketch, cleaned up transfer of the plan, and final print:

And here is the finished carved block loaded into the press:

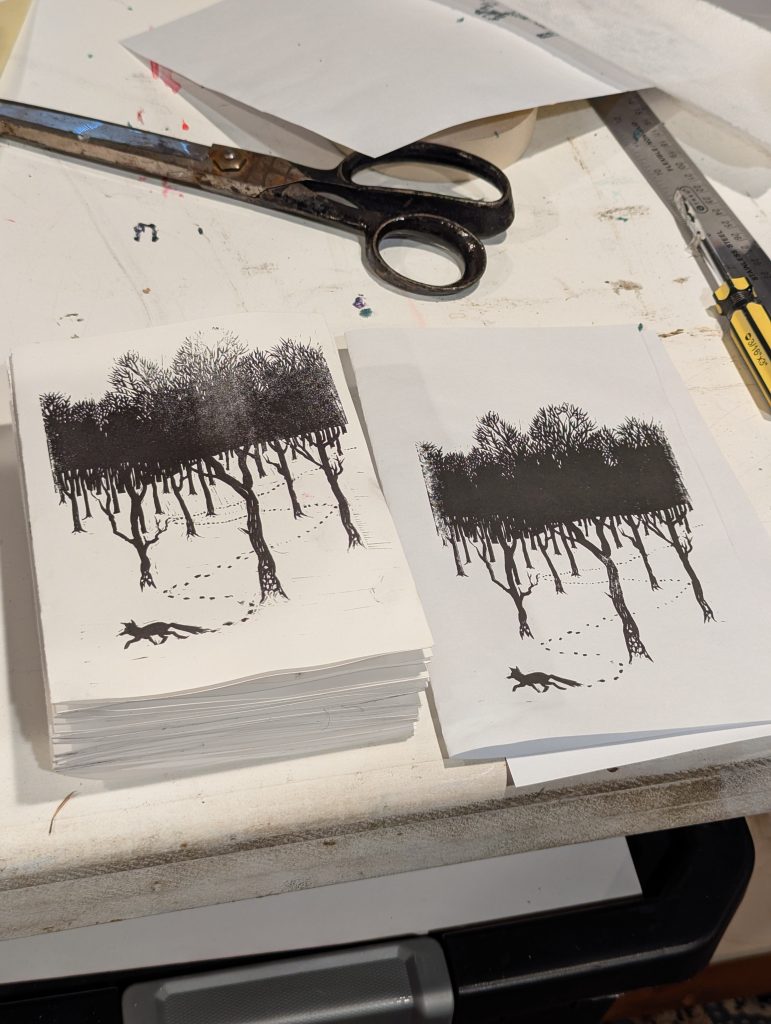

And the print run of greeting cards:

Overall quite pleased with the progress, and already planning print number four, my first attempt at a two color print on this press.

Thanks for following along!